sales@mittalsales.com

sales@mittalsales.com

PRODUCT Categoeries >>> ParasBack

Rubber Lubricant

PARAS high quality tuber lubricants makes the installation easy. Available in 50gm, 100gm, 250gm, 500gm, 1kg.

Rubber Ring Jointing Method

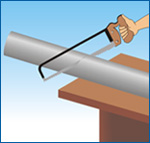

Cut the PARAS SWR pipe to the required length.

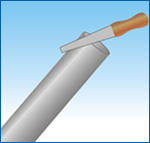

Chamfer the edge of the pipe Clean all the dirt & dust, make sure that the spigot and socket are thouroughly clean and dry.

Apply PARAS Rubber lubricant on the external surface of the chamfered end of the pipe and on the rubber gasket. Fit the rubber ring in to the groove of the pipe.

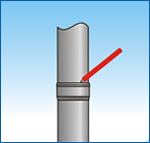

Confirm that ring seal is in position in the housing.

Push the pipe fully into the socket and mark the pipe depth in the socket using the marker.

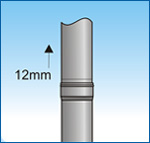

Pull out the pipe by 12mm from the socket register. This is very important it take care of thermal expansion and contraction.

Joining of C.I. and G.I. Pipes to PARAS SWR Pipes

Roughen the external surface of the pipe / fitting end with the file or sand paper. Apply a thin cote of solvent cement on the roughed surface with a brush. Sprinkle dry sand on the solvent cement and leave it to dry for few minutes. A rough base is ready for good bonding with the cement. Insert the solvent cement based PVC pipe in to the C.I. / A.C. socket & fill the gap with regular Portland cement.