sales@mittalsales.com

sales@mittalsales.com

PRODUCT Categoeries >>> ParasBack

uPVC SWR Drainage System

Advantages

- HIGH STANDARDS & WIDE RANGE

- MIRROR SMOOTH BORE-NO CHOCKING

- EXCELLENT CHEMICAL & CORROSION RESISTANCE

- LIGHT WEIGHT - EASY HANDLING

- HIGH IMPACT STRENGTH

- UV - STABILIZED (ALL WEATHER RESISTENCE)

- 100% LEAK PROOF JOINTS

- LONGER LIFE

- EASY CLEANING

- QUICK CONVENIENT INSTALLATION

- QUICK TESTING

- NO FILLING MATERIAL REQUIRED FOR JOINTING

- LEAST MAINTENANCE

- CAN BE COLOURED AS PER CHOICE TO MATCH BUILDING AESTHETICS

- ECONOMICAL uPVC SOIL WASTE & RAIN WATER (S.W.R.) DRAINAGE SYSTEM ALL WEATHER RESISTENCE, NO LEAKAGE, NO BREAKAGE, NO BLOCKAGE

PARAS is pioneer in introducing most cost effective & efficient drainage system (S.W.R.) which is fast replacing most of the conventional systems used in building industry. PARAS believes only in supplying quality products aimed at global market & this is backed up by state of the art equipment installed at the plant & technical know how available from the worlds best technology.

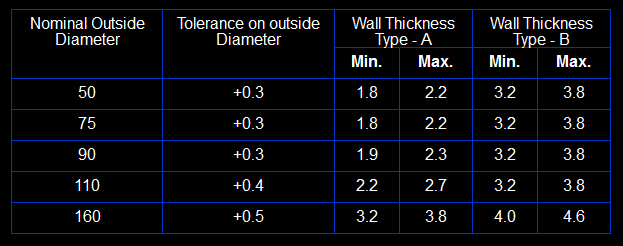

DIMENSIONS OF PIPES

(All dimensions are in mm)

Note : As per IS 13592-1992

Type-A : Pipes are recommended for use in ventilation pipe work & rain water application &

Type-B : Pipes are recommended for use in soil & waste discharge systems.

Pipes are available in 2,3,4,6,10 feet lengths in single socket & double socket with 'O' Ring / Rubber Ring and also Selfit / Pasting type.

Size & Range - SWR Pipes - 50mm / 75mm/ 90mm / 110mm / 160mm

Type A & Type B as per IS:13592-1992

SWR Fittings - 75mm/110mm - ISI/ Paras India / Aqua

50mm/ 90mm / 160 mm - Paras India

FITTING DIMENSIONS ARE AS PER DIN 19531 & DIN 19534 & CONFORMING TO IS 14735-99

(Rubber ring conforms to IS 5382)

Joining Instructions :

- Make sure that spigot end and inside of socket is clean and the sealing ring is placed evenly in the socket.

- When cutting pipes make sure they are cut square. Chamfer the end cut to an angle of 15° with a medium file.

- A correct depth of entry of the spigot into the socket is required to allow thermal movement. To achieve this, push spigot fully into the socket (remove sealing ring at this time) and make a mark on the spigot. Withdraw the spigot by 10mm & mark the spigot with a bold line. This bold mark indicates the correct depth of entry to allow the necessary expansion gap.

- Smear PARAS rubber lubricant evenly on the chamfered spigot and the sealing ring. Then insert the spigot into socket with light twisting motion. Pull out the pipe to allow 10mm expansion gap.

- The joint is now complete and requires no additional mastics, tape or cement or any other joining sealants.

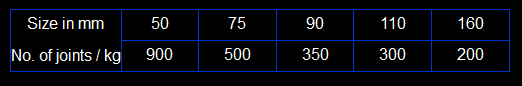

APPROX CONSUMPTION OF RUBBER LUBRICANT

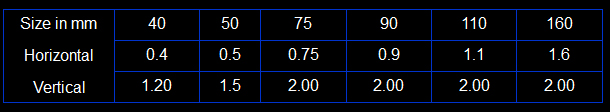

MAXIMUM SUPPORT DISTANCE IN METERS

PRECAUTIONS

- Only UV stabilized uPVC SWR pipes with rubber ring should be used. The regular uPVC Pipes with solvent cement joining when exposed to sun-rays/weather get brittle and brownish.

- Use only rubber lubricant for joining SWR Pipes & Fittings, where rubber ring is used

- Avoid over tightening of door caps. Proper placement of rubber ring should be confirmed before tightening.

- Avoid misalignment of vertical SWR Pipe stacks and incorrect spacing of Pipe clips.

- Cutting of UV stabilized SWR Pipe should be straight as diagonal cutting may leads to leakage.

- All entry to main stacks should be protected with water seal trap, wherever there is mixing of Soil & Waste lines.

- Keep a gap of 10mm between all UV stabilized SWR Pipes and Fittings to accommodate thermal expansion and contra- ction of pipes for longer life of the system.

- Smoke Test should be avoided and test plug / socket plug should be used for testing the lines.

- Horizontal lines within bathrooms should be cement encased and tested before compacting of sunken floor to avoid any accidental damages.

- For further technical information / assistance, the manufacturer to be contacted for required clarification