sales@mittalsales.com

sales@mittalsales.com

PRODUCT Categoeries >>> ParasBack

Paras - Super Flow Pipe & Fitting

High Pressure uPVC Solvent Weld Plumbing System - For Distribution of Potable Water

PARAS believes only in supplying quality products aimed at world market and this is backed up by state of the art equipment installed at the plant and technical know how.

High Pressure uPVC Solvent Weld Plumbing System

Features and Benefits

Stronger, Resilient and Longer Lasting : This system is highly resilient, tough and durable with high tensile strength and high impact strength. More over it is free from weakness caused by scale formation, rusting, weathering and chemical action and hence lasts for a life time. Minimum estimated life of PARAS Super Flow ASTM system is 50 years, and hence the system is a long term plumbing solution for building industry.

Excellent corrosion and chemical resistance :

This system is immune to electrolytic and galvanic corrosion and has excellent resistance to great number of chemicals like strong mineral acids.

Most suitable for carrying drinking water :

Being non metallic this system is free from corrosion and chemical action, hence absolutely safe for carrying potable water.

No sediment deposition, no reduction in bore size:

PVC is free from rusting, pitting or scale formation. Hence there is no particle deposition and the inner bore of the pipes remains undiminished throughout the life of the system.

Optimum flow rates :

The interior walls of the pipes and fittings have a mirror smooth finish. This ensures high flow rates and low frictional losses.

Simple and leak proof Joints :

Jointing can be done speedily with the special solvent cement supplied by the company which ensures 100% leak proof joints.

UV Stabilized :

JoiThis system is UV stabilized which eliminates the adverse affect of sunlight and weather. The system can therefore, be safely used for outdoor installations.

Quality of Solvent Cement :

JoiThis system is UV stabilized which eliminates the adverse affect of sunlight and weather. The system can therefore, be safely used for outdoor installations.

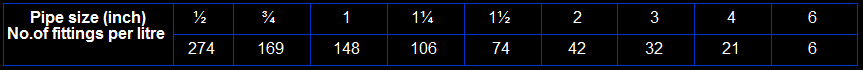

Consumption of Solvent cement

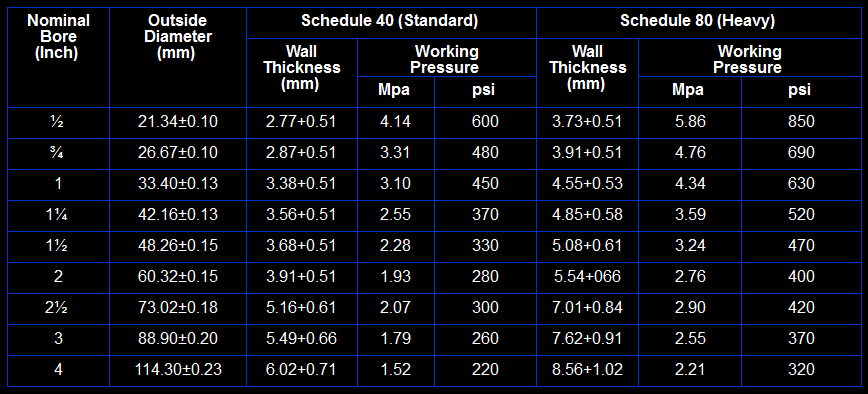

DIMENSION AND WATER PRESSURE RATING AT 23°C FOR UNTREADED PIPES AS PER ASTM D-1785 (PVC Compound grade equivalent to PVC 1120/2120)

Mpa=Mega Pascal 1Mpa=10 Kg/cm2 1kgf/cm2=14.20psi

Cutting

Cutting the pipe : Insert the pipe into the fitting and check that the interference occur about 1/3rd to 2/3rd of the socket depth. Too tight or too lose fitment may lead to leak, hence should be avoided.

Deburring

Cut the pipe square with hand saw with suitable guide or by pipe cutter. Joint prepar- ation : Chamfer or deburr pipe or both, approximately at 10°-15°. Remove burrs from inside and outside diameters with a knife file or abrasive paper.

Cleaning :

Remove any dirt, moisture, or grease from pipe end and fitting sockets with a clean dry rag.

Roughening

Solvent Cementing

Apply cement lightly but uniformly to inside of socket and outside of pipe and with a natural bristle nylon brush or suitable applicator. Apply a second coat of cement to the pipe end. Do not apply excessive cement in bell socket. Apply cement rapidly and be sure to completely cover all jointing surface area of the pipe and fittings.

Jointing

Immediately after applying the last coat of cement to the pipe (within 20 second) forcefully bottom the male end of the pipe in the socket, giving pipe or fitting ¼ turn to evenly distribute the cement. Remove excess cement from the pipe at the end of fitting socket. The joint must not be disturbed immediately after cementing, so that joint can properly cure. Allow cement to cure before pressurizing the system.

Recommended curing time is 12 hours.